Contact us

Lets get your project started.

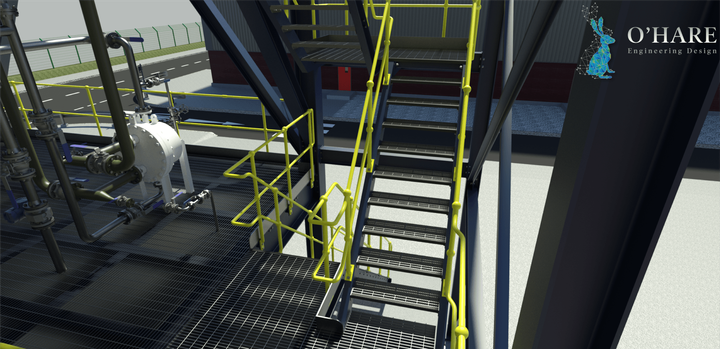

Over the past 20 years, we have worked with numerous clients in a variety of fields, enabling them to bring their vision to reality.

When you utilise us you'll be working with a team that are dedicated to you, with your best interests at heart.

Ready to take the next step in your engineering design project? Why not give us a call or drop us an email and we can arrange an informal chat..

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

Contact Us

We love to create and it shows.

Tell us what you have in mind

and we'll make it happen.

Blogs

Check out our latest blogs. Feel free to let us know your thoughts, we'd love to know what you think on the different subjects...