WHEN IS 3D LASER SCANNING NOT YOUR BEST OPTION?

WHEN IS 3D LASER SCANNING NOT YOUR BEST OPTION?

Date: 28th June 2022

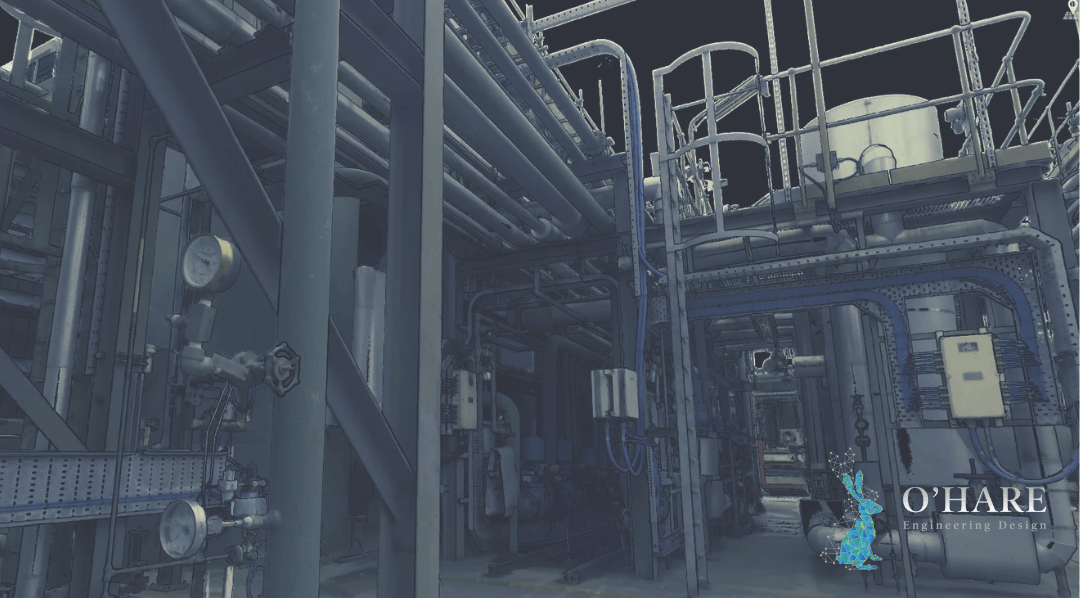

The decision to bring a laser scanning expert on board to map your site is not a decision a lot of organisations take lightly. And there’s usually a good reason why a site is considering 3D laser scanning as opposed to some of the other alternatives available to them.

There are many reasons why 3D laser scanning might be at the top of your options list, like its 1km scanning range, accuracy up to 0.8mm and its ability to collect dimensional information required for project deliverables, often missed by traditional surveying techniques.

But, despite all of these benefits, there are a couple of scenarios where 3D laser scanning isn’t the right option for the job, such as small cut and shut jobs and jobs where the line of sight doesn’t meet requirements.

Quick “cut and shut” jobs

Small cut and shut jobs are those small jobs that could just as easily be completed in a few hours with a notepad and a tape measure.

Some “experts” will push to bring in the laser scanner on the grounds that it will produce more accurate measurements and will require less time on site. In reality though, the laser scanner probably won't:

- Provide you with any more information than we can create measuring by hand.

- Result in any less time spent on site once you take into account the time it takes to set up and pack away the equipment.

- And, most importantly, it won't be cost effective for you as the buyer.

Line of sight limitations

In my blog “How does laser scanning actually work”, I go into much more detail about the ins and outs of 3D laser scanning, but one of the key factors to note about this process is its reliance on the laser's line of sight.

In essence, 3D environments are created by measuring the distance between the laser scanner and the point at which the light from the laser is reflected back when it hits an object. For most environments, it's easy to achieve complete scans by setting up from a couple of different locations within an environment. But sometimes, this can prove a little more challenging when you’re trying to scan, say, organic materials like a wall covered in ivy where there’s lots of variation in surface texture that our brains naturally interpret. Or in very small or high spaces where the required angle to create a complete scan is difficult to achieve.

Most of these limitations we have found manual get arounds for like scaffolding, cherry pickers and even sometimes drones. But very occasionally we come across sites (or sometimes areas of sites) where 3D laser scanning just isn't suitable for the job.

If you are unsure whether 3D laser scanning is the right choice for your project or site,

book a free laser scanning demo with us today. We’ll quickly be able to identify what the right path for your organisation or project is, even if that answer doesn’t involve lasers.